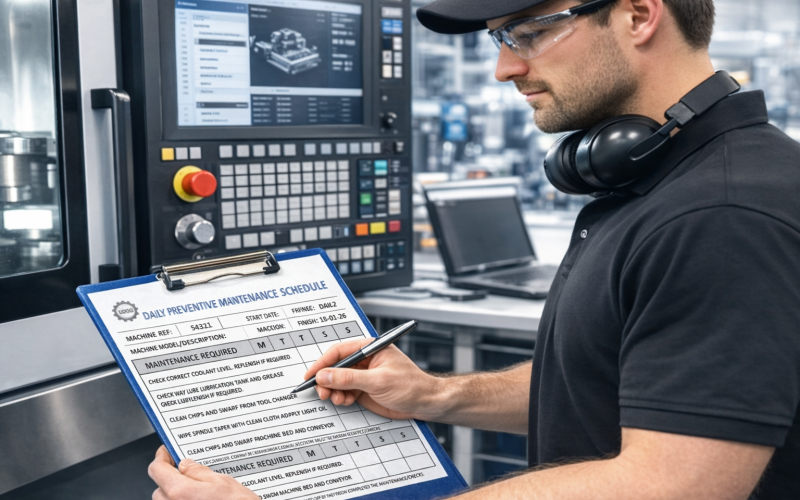

Maintenance records are often completed but rarely reviewed.

When data is collected only for compliance or reporting, patterns are missed and the same failures tend to repeat.

Why it fails Data collection is treated as an administrative task rather than a decision-making tool.

Fix Set a simple review rhythm. A short monthly review focused on recurring issues is often enough to prevent repeat failures.

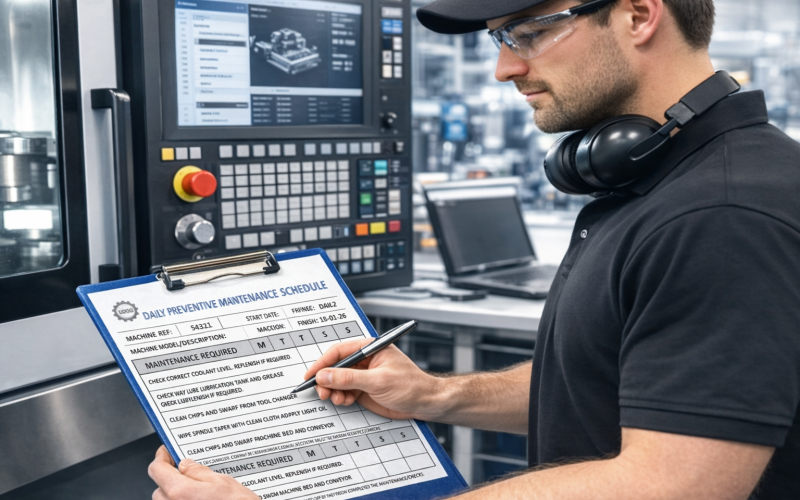

4. Maintenance Tasks Don’t Match Real Operating Conditions

Equipment rarely operates under ideal or steady conditions.

Changes in load, environment, and usage patterns mean that wear does not always follow the assumptions used when maintenance plans are first created.

Why it fails

Maintenance plans are often copied from manuals or past projects and never adjusted to reflect real operating conditions.

Fix

Review preventive tasks periodically and adjust them based on actual load, environment, and operating hours rather than original assumptions.

5. Poor Communication Between Maintenance and Operations